FEATURED PRODUCT: L65

Elliott Equipment Company is proud to announce its newest HiReach material handling aerial work platform, the L65.

The L65 has been engineered from the ground up as a replacement for Elliott’s L60. Designed to reduce weight, increase reach and lifting capacity, and improve serviceability over the outgoing L60, the L65 provides operators with a high-performance tool that costs less to own and has a smaller carbon footprint.

KEY BENEFITS

- 65-foot working height — 3% increase

- 59-foot side reach — 5% increase

- 600 lb. platform capacity — 20% increase

- Over 3,300 lbs. of toolbox capacity on non-CDL chassis — 55% increase

- 5,900 lb. main boom lift capacity (63% increase at full extension)

- User choice of single-stick or three-stick remote controls

- 160-degree platform rotation — 78% increase

- Stow & Go platform jib with unrestricted 500 lb. capacity

- Bluetooth remote diagnostics improve serviceability and reduce downtime

- Short-jack capability with one side vertical outrigger deployment for confined spaces

- Low profile bed with three step bumper improves access

- Integrated tie down rails and toolbox installation improve flexibility

- Four plate boom design reduces deflection

- Lower control station with phone charger

- Rounded cable carrier reduces chafing and improves serviceability

- 33% fewer hydraulic fittings reduce potential leaks

- Automotive grade electrical harnesses

- Heavy duty worm gear for leveling and rotation

- Reverse mount leveling cylinder increases performance

- Controls auto slow approaching offside lockout

- Manifold at upper controls improves serviceability

- ANSI A92.2 compliant in all modes of operation

- Backed by lifetime structural warranty

ABOUT THIS UNIT

Elliott is excited to introduce the new L65. The L60 was one of our most popular models, and we have listened closely to our customers over the years to design the L65 to offer greater performance, less weight, better ergonomics, and easier serviceability than anything else in its class.

He added, “We intend to use the L65 as an anchor point for our future HiReach products. We have a robust product pipeline and look forward to introducing several other new class-leading designs in the coming months.”

‘Built For You’ Testimonial

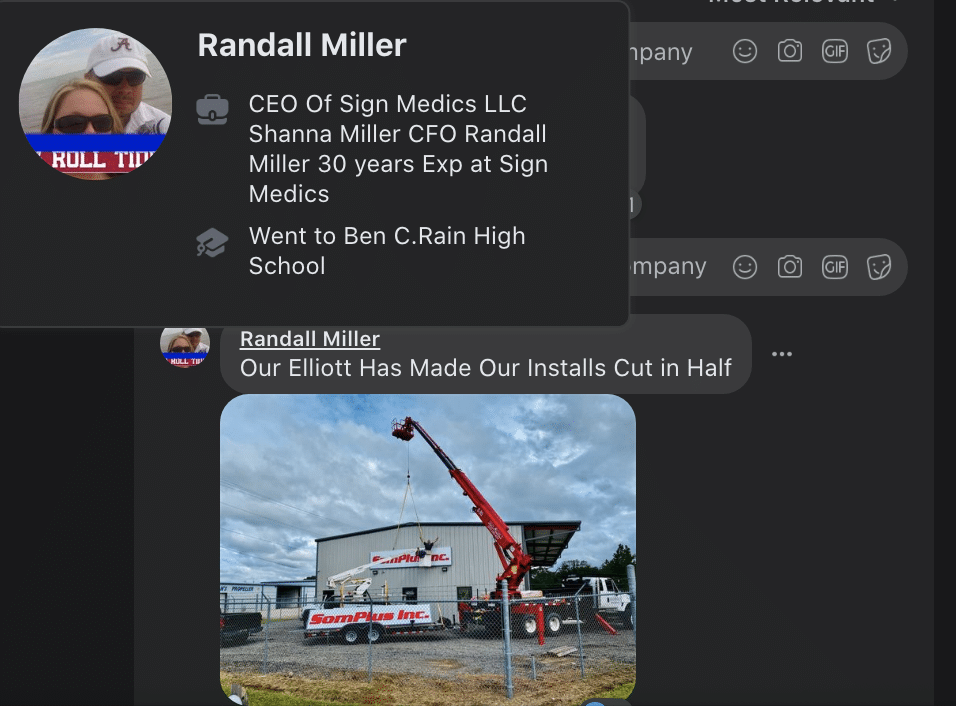

“Our Elliott has made our installs cut in half.”

- Randall Miller, CEO, Sign Medics LLC

EMPLOYEE PROFILE:

Pablo Guerrero

What is your Job Title?

I.T. lead for lines 1, 2, and 3.

When did you join Elliott?

About 8 years ago.

What do you like best about working for Elliott?

The people I work with, they are always willing to help.

What do you consider your biggest accomplishment at Elliott?

Starting in the wash bay and moving up to my lead position.

What is your favorite Elliott product and why?

1800, the units are very simple, but only if they don’t have remotes.

What are your personal hobbies?

I love fishing even if I’m not good at it.

What is your all-time favorite movie, band/musician, or TV series? Dragon Ball Z (the old series)

What is your favorite sports team?

If I watched sports and had a favorite team, it would have to be the Nebraska Cornhuskers.

Tell us about your family, pet(s), or give a fun fact about yourself!

Fun fact: I have a really good poker face, but I don’t play poker.

SAFETY TIP: INSPECTIONS

This month we are focusing our safety tip on the importance of monthly inspections.

Monthly and annual inspections act together to ensure all components of an aerial work platform are in working order while also providing peace of mind to owners whose businesses depend on these important assets.

Routine inspections collect critical information that helps users keep equipment in service and ensure jobs are completed safely.

SALES TIP:

EZ Crib Outriggers = Efficiency

Did you know that Elliott’s EZ Crib Outriggers significantly reduce load and unload times? Plus, 30 inches of additional penetration reduces the cribbing needed on a job, saving a user’s time … and back.