BIG THINGS AHEAD: WHAT’S COMING FROM ELLIOTT IN 2025

At Elliott Equipment Company, 2025 is shaping up to be a milestone year for us and for you. We’re bringing new innovations, major industry events, and even more ways to help you work smarter and more efficiently.

This year, we’ll be hitting the road to showcase our latest advancements at three of the most important industry trade shows: the ISA Sign Expo in Las Vegas in April, the EUFMC Fleet Managers Conference in Williamsburg in June, and The Utility Expo in Louisville in October. These events provide opportunities to see our newest equipment in action, connect with our team, and explore how Elliott continues to push the limits of quality, reliability, and efficiency.

But that’s just the beginning. We are expanding our product lineup with new solutions designed for the way you work, and we’re refining our operations through EECOS, our lean manufacturing system, to ensure every Elliott machine delivers the performance and dependability you rely on.

As always, our focus remains on our customers, operators, fleet managers, and dealers. We are committed to helping you do more with less effort, maximize uptime, and get the job done right.

Stay tuned for more updates as we make 2025 a year of progress, innovation, and success together.

BEHIND THE BUILD:

SUBASSEMBLY WORKCENTER

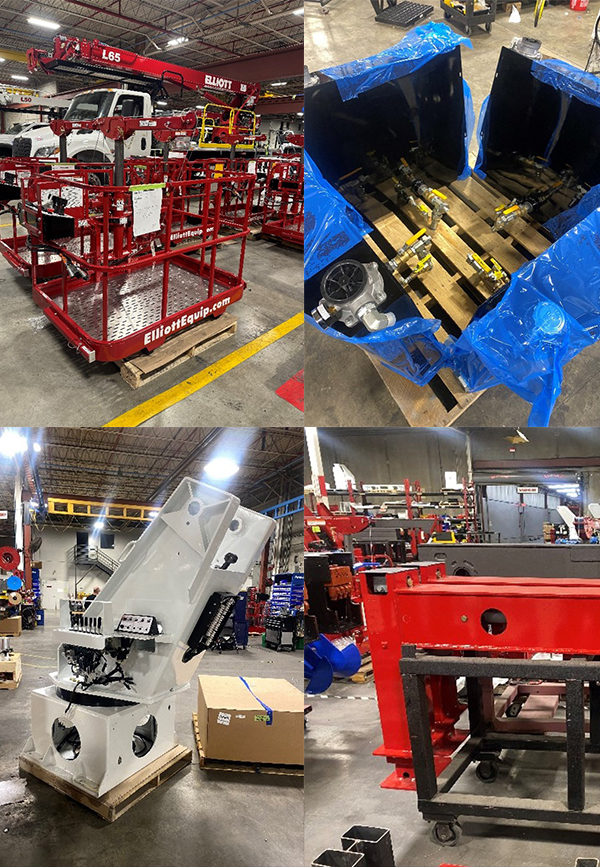

Our Behind the Build series offers a sneak peek into how Elliott machines are made, focusing on craftsmanship, manufacturing, and the people behind the scenes.

This month, we’re shining the spotlight on our Subassembly workcenter, a key department responsible for building essential components that go into our final products.

What Does Subassembly Do?

The Subassembly team plays a crucial role in assembling a variety of components that are later integrated into Elliott machines. Some of their key responsibilities include building baskets, turrets, outriggers, hydraulic tanks, and gen subs.

In addition to these, the Subassembly team works on many other smaller components that contribute to the overall functionality and performance of our machines.

What’s New in Subassembly?

A major upgrade is underway in Subassembly with the development of a new instruction center designed to improve efficiency and support new employees—especially those learning to build the D47i.

This visual standard work system provides step-by-step guidance, ensuring consistency and making onboarding smoother.

At Elliott, we’re always looking for ways to improve our internal processes to enhance efficiency, support our team, and deliver the best possible products to our customers. Innovations like the new instruction center in Subassembly are just one example of how we continue to evolve and refine our operations to maintain the highest standards of quality and performance.

Stay tuned for more updates as we highlight the incredible work happening across our company!

THE SIGN & LIGHTING EQUIPMENT THAT WORKS FOR YOU

Hiring qualified technicians is one of the biggest challenges in the sign and lighting industry—but Elliott makes it easier. Our non-CDL HiReach sign trucks and BoomTruck cranes allow you to hire from a larger talent pool and get new team members working faster, without the delays and costs of CDL certification.

Beyond hiring, Elliott HiReach aerials are built to keep your business running smoothly. With industry-leading reliability, you can minimize unplanned downtime and keep your jobs on schedule. And with best-in-class side reach, your crews can do more from a single setup, reducing repositioning time and increasing productivity on every job.

For companies installing and maintaining signs and lighting, Elliott’s non-CDL lineup—including the M43, V60, L65, and M87—delivers the working heights, reach, and versatility you need. Dynasmooth controls, fast outrigger setup, and our exclusive “Office in the Sky” platform accessories make each job easier, safer, and more efficient.

When it comes to hiring, reliability, and getting more work done with fewer moves, Elliott is the clear choice—because it’s Built For You. Let’s talk about how we can help your business grow.

ELLIOTT IN THE WILD

CAD Signs is doing a bit of maintenance work at their local IKEA in Miami. Their G85 is the perfect machine to get the job done!

Want to be featured? Share photos of your Elliott equipment in action on social media and tag us!

SPOTLIGHT ON BRAD WEBER: MANUFACTURING ENGINEER

What is your Job Title? Manufacturing Engineer

When did you join Elliott? February 2024

What do you like best about working for Elliott? The great people!

What do you consider your biggest accomplishment at Elliott? Boom cart design.

What is your favorite Elliott product and why? The 3095R because I have a lego model of one at my desk.

What are your personal hobbies? Spending time with my wife, managing the AV booth at my church, collecting firearms, and maintaining my 125+ year old house.

What is your all-time favorite movie, band/musician, or TV series? Lord of the Rings (I like the books more than the movies though).

What is your favorite sport and team? The Minnesota Vikings.

Tell us about your family, and pet(s), or give a fun fact about yourself! I met my wife at church 6 years ago, and she declined the first time I asked her on a date. We’ve been happily married for 3 years now though, so I guess I got the last laugh!

SPOTLIGHT ON SAFETY: BUILDING A STRONGER, SMARTER FUTURE TOGETHER

At Elliott, safety isn’t just a policy—it’s who we are. As part of the Elliott family, you share in our commitment to building the safest, most reliable equipment in the industry. Just as you rely on Elliott machines to protect your crews in the field, we prioritize safety at every stage of our production process to ensure the quality and dependability you expect.

Our safety audit program is one of the many ways we reinforce this commitment. Regular safety checks and recognition programs keep our team focused on best practices, ensuring that every Elliott machine is built with the same care and attention that you bring to your own work.

From leadership discussions to hands-on training, we continually refine our processes to create a safer, more efficient workplace. We encourage you to bring the same mindset to your operations—because when safety comes first, productivity and quality follow.

A strong safety culture doesn’t happen by accident. By working together—on the production floor and in the field—we can protect our teams, uphold the highest standards, and continue delivering the industry’s most trusted equipment.

Thank you for being part of the Elliott commitment to safety and excellence!

STOCK UP ON NEW ELLIOTT APPAREL, GEAR, and GIFTS

Elliott Equipment Company is excited to unveil our new online store at elliottbrandstore.com! Show off your Elliott pride and stock up on apparel, work and travel accessories, drinkware, tools, gifts, and more. With the holiday season right around the corner, there’s never been a better time to impress the machine lovers in your life.